In-space Servicing, Assembly, and Manufacturing (ISAM)

ISAM’s mission is to mature robotic and servicing technologies to make what was once thought to be impossible in space a reality.

Ushering in an Era of Affordable,

Sustainable, and Resilient Spaceflight

NASA’s In-Space Servicing, Assembly, and Manufacturing (ISAM) office at Goddard Space Flight Center is challenging the status quo of “One and Done” missions and developing groundbreaking technologies to service spacecraft and pioneer in-space assembly and manufacturing.

In-space, Servicing, Assembly, and Manufacturing

Robots are poised to make what was once thought to be impossible in space a reality. In-Space Servicing, Assembly, and Manufacturing (ISAM) aims to extend the lifespan of satellites, to assembling massive life-seeking telescopes in space, to refueling and repairing spacecraft on journeys to distant locations, the possibilities are endless.

Goddard ISAM Capabilities

To enable ISAM missions, Goddard has an array of robotic, simulation and cooperative servicing capabilities that are needed to test and validate satellite servicing hardware and tasks. Through testing, data collection, and simulations – these capabilities have become part of a knowledge base that’s used to further ISAM goals.

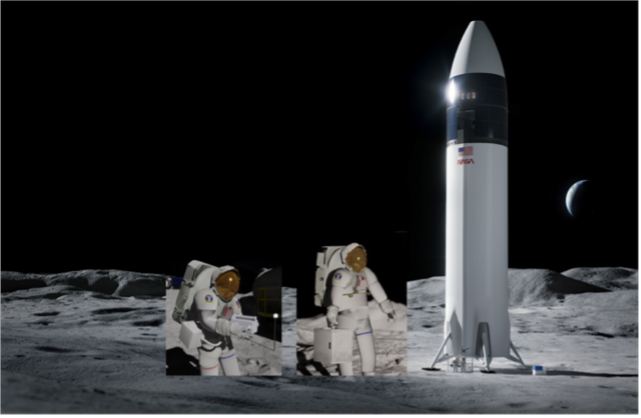

Robotic Technology

In-space robotics requires high maneuverability to accomplish complex tasks. Opening a door, grabbing a pencil, pouring a glass of water; these are all are examples of simple, everyday tasks that use your arm. Like your arm, the NASA servicing robot has “seven degrees of freedom”— a three-axis shoulder, a pitch actuator at the elbow, and a three-axis spherical wrist. Other features include a six-axis force/torque sensor at the end of the arm, and a flex harness that routes data, power, and video.

Simulation Capabilities

These Earth-bound facilities use industrial robots, a motion-based platform, and customized algorithms to create simulations of space operations on large and small scales. Capabilities range from simulating a robotic arm servicing a satellite in space, to practicing how a satellite would approach an object (such as a client spacecraft or a rotating asteroid), to seeing how fuel sloshing in a tank or thruster firings would affect a satellite’s behavior in microgravity.

Cooperative Servicing

A spacecraft or a satellite that’s ‘prepared’ is an object equipped with interfaces and accommodations intentionally designed to enable in-space servicing. For example, fiducial markers, are low-cost, low-mass tools that NASA uses to bridge the gap between legacy and prepared satellites. Going forward, it is NASA’s goal to incorporate prepared interfaces and accommodations to enable autonomous satellite servicing tasks, like repairs or refueling operations.

ISAM Projects

Current ISAM missions and projects range from enabling cooperative servicing techniques, to developing unique robotic tool drive systems along with complex software, and providing hands-on technical support for space robotics missions. To learn more about the current ISAM projects at Goddard, explore below!

LESSH (Lunar Experiment Support System & Handling)

The Lunar Experiment Support System and Handling (LESSH) is contributing to NASA’s plan to deploy science instruments on the moon near a South Pole landing site beginning with the Artemis III mission. LESSH Placed is an instrument package that can be deployed by astronauts and re-charged via an Artemis vehicle, enabling extended science operations. LESSH Placed provides astronaut-rated battery power, wireless communications, high speed data processing, and thermal management.

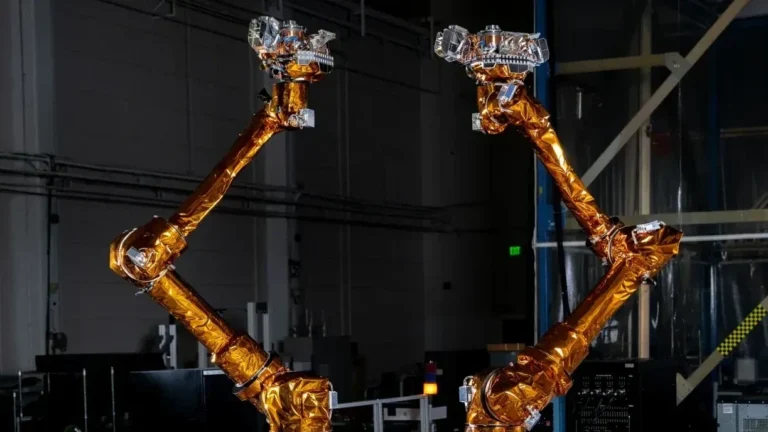

RSGS (Robotic Servicing of Geosynchronous Satellites)

Due to Goddard’s ISAM expertise, NASA is supporting the RSGS Mission at the Naval Research Laboratory (NRL). Pulling from previous mission knowledge, like the agency’s On-orbit Servicing, Assembly, and Manufacturing 1 (OSAM-1) mission and other relevant efforts, NASA is providing hands-on support to RSGS in the areas of space robotics, systems engineering, spacecraft subsystems, integration and testing, operator training, and spaceflight operations.

FFR (Fly Foundational Robots)

NASA is fostering the commercial industry through the SBIR award program to develop an advanced in-space robotic payload as part of the agency’s FFR initiative. The payload consists of a mobile robotic arm capable of dexterous manipulation, autonomous tool use, and—uniquely—walking across spacecraft surfaces in microgravity. These demonstrations could lay the groundwork for robotic servicing, inspection, and assembly tasks in orbit. A test of the mobile robotic arm in orbit will be conducted by a commercial flight provider through NASA’s Flight Opportunities program.

ISAM Facilities

Goddard’s ISAM facilities have unique simulation capabilities that use a variety of satellite and space payload mockups to complete various tasks like grapple simulations, satellite servicing simulations, and interactive dynamic simulations.

Contact NASA Goddard’s ISAM Team

To learn more about our facilities and how to potentially partner with us, how to license technology, or ask questions about ISAM at NASA Goddard please reach out.