Advanced Manufacturing

Empowering NASA’s Missions with Advanced Manufacturing for Spaceflight Hardware and Scientific Instruments

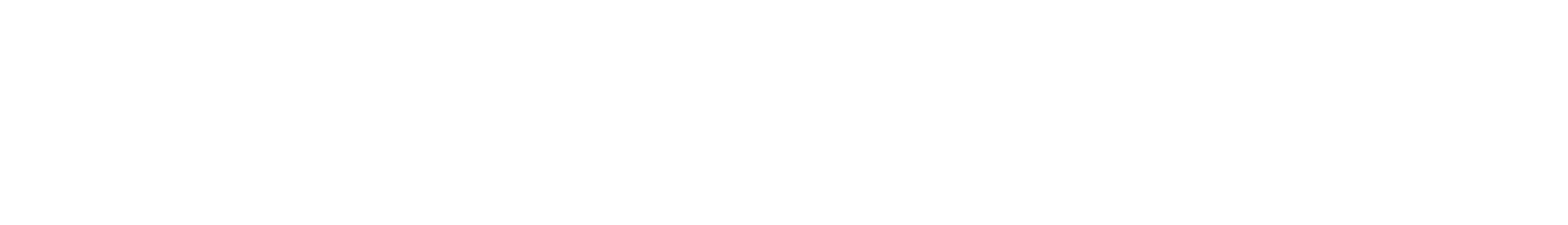

Advanced Manufacturing at the Goddard Space Flight Center provides extensive mechanical capabilities and technology development essential for the design, analysis, fabrication, assembly, integration, and verification of scientific instruments and support platforms for various missions, including ground-based, suborbital, and orbital science and exploration. The Advanced Manufacturing Branch (AMB) specializes in delivering comprehensive advanced manufacturing services across the entire product lifecycle, from concept to completion. With over 60 years of expertise, the branch provides cutting-edge solutions that enable high-quality manufacturing for NASA.

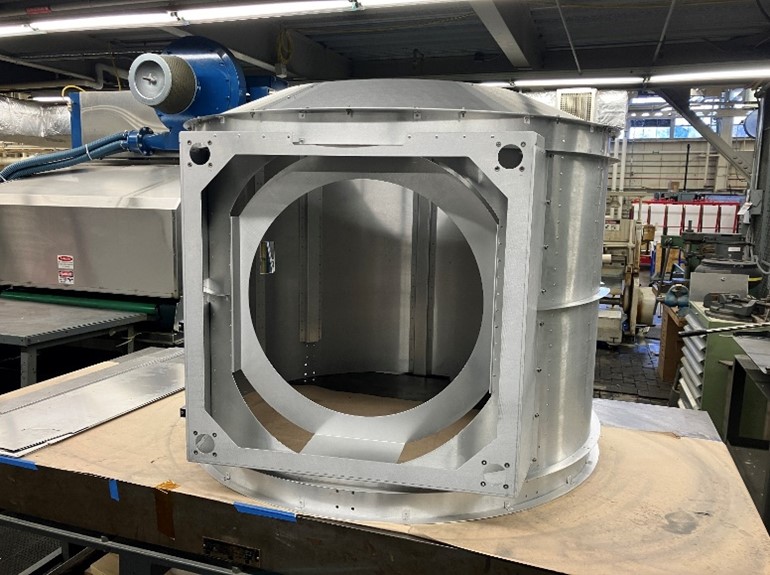

The AMB is responsible for managing a fully equipped manufacturing facility that addresses the research and development requirements of the Center while supporting hardware fabrication for multiple NASA initiatives. The facility is equipped with conventional machining tools, numerically controlled (NC) machining centers, sheet metal fabrication equipment, electroplating capabilities, composite fabrication tools, a metrology laboratory that supports mechanical inspection, spacecraft alignment, integration and test, flight-certified fastener inventory, and an innovation laboratory. Collaboration with engineers and scientists is essential for conceiving, designing, producing, and evaluating complex sensors, instruments, and spacecraft components to ensure they meet or exceed scientific performance goals. Cutting-edge technologies and processes are incorporated into the design and manufacture of spaceflight hardware, enabling NASA’s flight programs to make groundbreaking discoveries.

The AMB features several assembly areas equipped with overhead cranes and assembly tables, with dimensions of 42’ x 23’ x 40’, 36’ x 40’ x 35’, 28’ x 14’ x 12’, and 32’ x 44’ x 30’. Two dedicated cleanroom environments are provided: a class 1K measuring 27’ x 19’ x 8’ and a class 10K measuring 28’ x 22’ x 8’. Additionally, there is bonded storage space of 44’ x 42’ x 12’ and a mezzanine area on the second floor measuring 60’ x 43’ x 8’. Overhead cranes with capacities ranging from 1 to 20 tons are accessible throughout the laboratories.