ETD Mechanical Systems Division

MSD | Code 540

Engineering Innovation at the Forefront

The Mechanical Systems Division is where innovation drives exploration and expertise shapes the future. It’s team is dedicated to pushing boundaries, from ground-based research to cosmic exploration, advancing discovery one visionary step at a time.

Materials Contamination and Coatings Branch (541)

The Materials Contamination and Coatings Branch serves as Goddard Space Flight Center’s comprehensive technical authority for materials science, contamination control, and coatings systems, providing broad support capabilities to ensure mission and performance requirements are met for flight and ground support systems across NASA facilities and government agencies. The branch acts as Goddard’s focal point for selecting, controlling, and reviewing all materials, processes, and lubricants for Goddard flight missions while serving as the central contact for investigating spacecraft materials problems and failures, assisting management with policy development, and maintaining direct interfaces with flight projects from conceptual design through final application. Branch teams manage research and development programs to advance materials technology, operate specialized contamination laboratories for measuring surface properties and outgassing rates using advanced equipment like BRDF and MOLEKIT systems, performs modeling analyses to predict contamination effects and environmental degradation, and conducts flight qualification testing of coatings and thermal control surfaces. Additionally, the branch develops new software and coating technologies to meet advanced spacecraft requirements, maintains databases of thermal property data, partners with NASA centers and international organizations on flight experiments, contributes to agency-wide contamination and coatings standards, and disseminates knowledge through technical publications while ensuring contamination system design integrity from concept through end-of-life for all Goddard-managed spacecraft, instruments, and missions including space science, Earth science, lunar, and planetary exploration programs.

Contact Code 541 Key Personnel

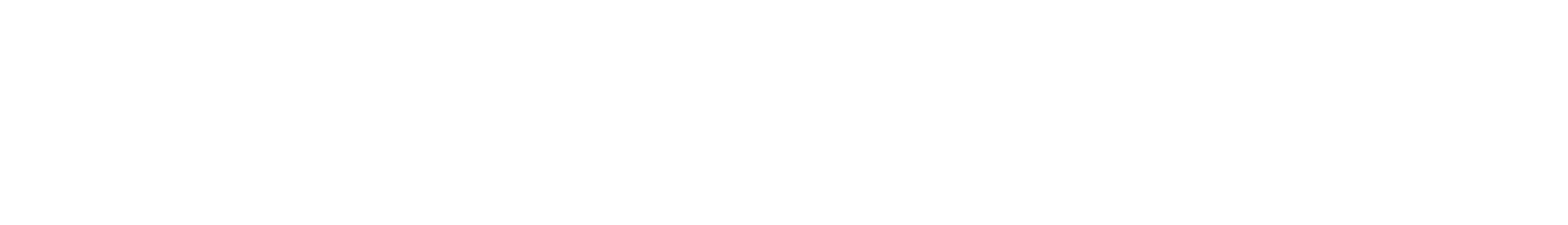

Mechanical Engineering Systems and Analysis Branch (542)

The ETD Mechanical Engineering Systems and Analysis Branch provides comprehensive mechanical engineering support throughout all phases of spacecraft and instrument development. The branch performs structural and mechanical design, analysis, fabrication, assembly, and verification for in-house spacecraft structures, deployment systems, and ground support equipment, while conducting multidisciplinary analyses to ensure optimal system designs and compatibility. Their capabilities encompass conceptual studies for proposed missions, generation of mechanical systems requirements including structural designs and verification plans, and advanced research into new structural concepts and precision deployment systems utilizing composites and advanced aerospace materials. The branch leverages finite element analysis for structural qualification, performs complex analytical predictions of flight loads and environmental responses, and conducts specialized analyses such as Structural Thermal Optical Performance (STOP) and jitter studies. Additionally, they develop and execute comprehensive testing programs to satisfy safety requirements, provide graphical simulations for multidisciplinary system studies including robotic motion and field of view analyses, and coordinate mechanical interfaces between all system components. The branch also manages computer facilities and software tools while conducting ongoing research to advance computational capabilities for accurate systems design, analysis, and simulation of current and future flight systems.

Contact Code 542 Key Personnel

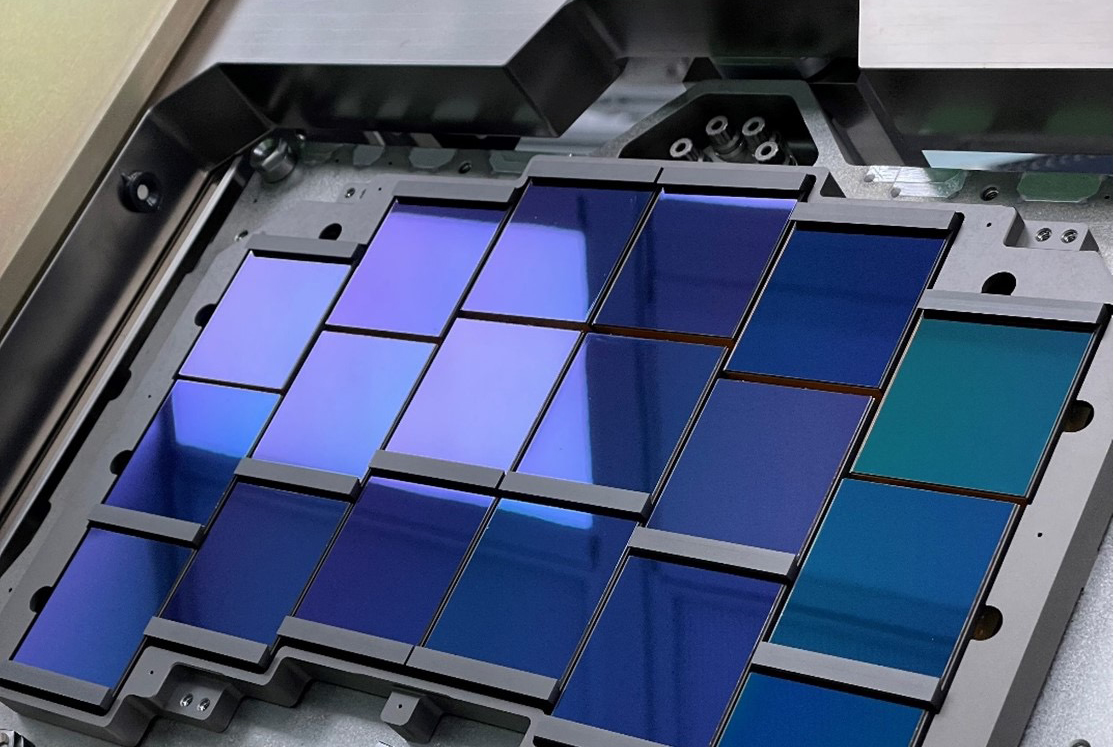

Mechatronics and Robotics Branch (544)

The Mechatronics and Robotics Branch provides multi-disciplinary support in areas of electromechanical systems engineering, including precision mechanisms, optomechanical systems, control electronics and robotics. The codes capabilities and technology development expertise to conceptualize, define, design, analyze, fabricate, integrate, and test world-class scientific instruments and spacecraft components in support of a variety of ground-based, suborbital, orbital, and interplanetary space and Earth science missions. The Branch collaborates closely with scientists, researchers, and other engineering disciplines to ensure the seamless integration and performance optimization of these cutting-edge components, pushing the boundaries of exploration and innovation in space technology.

Contact Code 544 Key Personnel

Thermal Engineering Branch (545)

The Thermal Engineering Branch at Goddard plays a crucial role in developing and applying technology to meet the thermal requirements of spacecraft and scientific instruments. The Branch develops and integrates thermal control systems, providing support throughout project lifecycles, from concept to flight operations. Conducting research in the Thermal Technology Development and Demonstration Facility, they push the boundaries of thermal control technology. The Branch offers technical oversight and support to various stakeholders, including flight projects and instrument developers, while also contributing to the development of thermal software packages to enhance engineering practices.

Contact Code 545 Key Personnel

Advanced Manufacturing Integration and Test Branch (547)

The Advanced Manufacturing Integration and Test Branch serves as a comprehensive engineering organization responsible for the design, manufacturing, integration, and testing of spaceflight hardware, science instruments, special payloads, and spacecraft systems from initial concept through environmental qualification. The branch provides manufacturing and fabrication support for state-of-the-art science instruments and spacecraft components, offering quick-reaction design, development, and modification services for experiments spanning ground-based aircraft, balloon, spaceflight, and laboratory research applications while resolving manufacturing difficulties and providing design review services for producibility and fabrication practicality. Code 547 manages the integration of components and subsystems after completion of verification programs, conducting comprehensive environmental testing per project requirements, and is responsible for acquiring, managing, and operating integration and environmental test facilities while advancing test techniques and methodologies. The branch maintains specialized cadres of Integration and Test managers, Test Conductors, and technicians to plan, coordinate, and execute integration activities, providing engineering expertise, facilities, instrumentation, and technical support for structural and mechanical integration, testing, handling, and launch operations while managing clean room operations and laboratory space allocation for flight system integration functions.

Contact Code 547 Key Personnel